how to get elastic modulus from hardness test|elastic modulus : dealers Dear Prof. Suo, I apologize for late response, earlier I was using internet . Resultado da 14 de set. de 2023 · A NetBet oferece as melhores apostas de futebol do mercado, com várias vantagens, como a promoção Criar Aposta, odds aumentadas e várias seleções exclusivas. Vasco x Fluminense O clássico carioca entre Vasco e Fluminense, marcado para a 23ª rodada do .

{plog:ftitle_list}

Resultado da Ouça ao vivo Rádio CBN Rio 92.5 FM - Rio de Janeiro / RJ - Brasil [Jornalismo (all news),Futebol,Debates e Entrevistas]. Acesse essa rádio .

Elastic modulus is an intrinsic material property and fundamentally related to atomic bonding. Hardness is an engineering property and for some materials it can be related to yield strength.

Dr. Hector Gomez . Associate Professor of Applied Mathematics University of A .At the same time, we will get a much better sense of whether the community would .

Dear Prof. Suo, I apologize for late response, earlier I was using internet .

Only elastic property enters the consideration if inelastic deformation .Properties include elastic modulus, ductility, hardness, and various measures of strength. Mechanical properties desirable to the designer, such as high strength, usually make .amount of elastic strain can be determined by unloading the specimen at some deformation, as at point A. When the load is removed, the specimen shortens by an amount equal to the stress . A newly developed approach to plasticity makes it possible to include elastic effects, which play a major role when the indenter is blunt. After being reviewed, the new theory is applied to explain several of the .

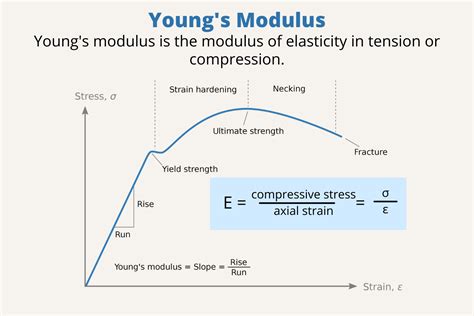

Two mechanical properties, elastic modulus, and hardness can be determined by nanoindentation. The elastic modulus (E), often referred to as Young’s modulus is the ratio of stress (σ) to strain (ε) when deformation is totally elastic. The basic mechanical properties of hard and superhard coatings, i.e. the microhardness H, effective Young's modulus E * and elastic recovery W e, are evaluated .

In either case the elastic modulus can be measured by using a device called instrumented indentation tester (IIT) also known by several other names such as a depth .

what is elastic modulus

rigidity vs elastic modulus

kd tools compression tester parts

The hardness is found by dividing the load by the area of contact. Shape of the unloading curve provides a measure of elastic modulus. Anthony C. Fischer-Cripps, Principles of . Modulus of elasticity is the ratio of stress to strain in a material. This is shown in the slope of the stress-strain-curve (link). Stress-strain is non-linear for elastomers, which makes it very dependent on the conditions of .In case of tensional stress of a uniform bar (stress-strain curve), the Hooke’s law describes behaviour of a bar in the elastic region. In this region, the elongation of the bar is directly proportional to the tensile force and the length of the bar and inversely proportional to the cross-sectional area and the modulus of elasticity.Up to a limiting stress, a body will be able to .

How to calculate modulus of elasticity? Following are the different ways to find the modulus of elasticity:-A) If the values of stress and the corresponding strain are known then the modulus of elasticity can be calculated by using the .Elastic region Shear stress, τ Shear strain, γ Fracture Shear strength Yield point θ 12 Hardness • Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg • Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. • Vickers Hardness Test: Pyramid shape indenter ()( 2 2 ) 2 Db Db Db Di F .Young's Modulus is reported commonly as N/mm2 (lbs/in2), MPA (psi). Typical graph showing modulus of elasticity / Young’s Modulus: We provide force measurement instruments and materials testing machines for elasticity testing. Request more information to see how we can help you with an elasticity testing solution that suits your needs.

Young's modulus, , quantifies the relationship between tensile or compressive stress (force per unit area) and axial strain (proportional deformation) in the linear elastic region of a material: [2] = Young's modulus is commonly measured in the International System of Units (SI) in multiples of the pascal (Pa) and common values are in the range of gigapascals (GPa)."Hardness" in the elastic range—a small temporary change in shape for a given force—is known as stiffness in the case of a given object, or a high elastic modulus in the case of a material. . inferring the latter from the former is far from simple and is not attempted in any rigorous way during conventional hardness testing.

The area up to the yield point is termed the modulus of resilience, and the total area up to fracture is termed the modulus of toughness; these are shown in Figure 13. The term “modulus” is used because the units of strain energy per unit volume are \(N-m/m^3\) or \(N/m^2\), which are the same as stress or modulus of elasticity.

In case of tensional stress of a uniform bar (stress-strain curve), the Hooke’s law describes behaviour of a bar in the elastic region. In this region, the elongation of the bar is directly proportional to the tensile force and the length of the bar and inversely proportional to the cross-sectional area and the modulus of elasticity.Up to a limiting stress, a body will be able to . The modulus of elasticity, also known as Young's modulus, is a material property and a measure of its stiffness under compression or tension. Stress is applied to force per unit area, and strain is proportional change in length. The modulus of elasticity formula is simply stress divided by strain. . To test the strength of materials, an . The elastic modulus and hardness are strongly correlated with the microstructure of polycrystalline specimens, because pores and boundaries will reduce the elastic modulus and hardness [13]. Transparent polycrystalline silicon nitrides are free of pores and grain boundary (GB) are important factor affecting the hardness and transparency of .

Hard materials are currently characterized by their hardness, H, effective Young's modulus E * =E/(1−ν 2) and elastic recovery W e, where E and ν are the Young's modulus and the Poisson ratio, respectively. For hard coatings, these quantities can easily be determined from loading/unloading curves measured by nanoindentation or instrumented microhardness testing. where E and v are the elastic modulus and Poisson’s ratio for the specimen, and E i and v i are the same quantities for the indenter. For the diamond indenter, E i = 1141 GPa and v i = 0.07. The accuracy of hardness and modulus measurement depends inherently on how well the contact stiffness and contact area can be measured experimentally.The Young’s modulus of elasticity of Titanium is 116 GPa. Hardness of Titanium. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard . Measure of Modulus. Durometer is as much a measure of the modulus of an elastomeric material. Modulus of elasticity is the ratio of stress to strain in a material. This is shown in the slope of the stress-strain-curve ().). Stress-strain is non-linear for elastomers, which makes it very dependent on the conditions of measurement.

where τ is the shear stress or shear strength, MPa; γ is the shear strain; and G is the shear modulus or the modulus of rigidity, MPa. Eq. 3.3 enables us to define the shear modulus as follows: “the shear modulus is the ratio of shear stress to shear strain”. A large shear modulus value indicates that the solid is highly rigid i.e. a large force is required to .

Nanoindentation, or instrumented indentation, has proven to be an extremely useful technique to characterize the mechanical properties of metals (Ref 1) and ceramics (Ref 2) at the microscale.Nanoindentation provides information on the measurement of hardness and elastic modulus (Ref 3, 4).This technique has been successfully used to measure, in .where E and v are the elastic modulus and Poisson’s ratio for the specimen, and Ei and vi are the same quantities for the indenter. For the diamond indenter, Ei = 1141 GPa and vi = 0.07. The accuracy of hardness and modulus measurement depends inherently on how well the contact stiffness and contact area can be measured experimentally. The

In case of tensional stress of a uniform bar (stress-strain curve), the Hooke’s law describes behaviour of a bar in the elastic region. In this region, the elongation of the bar is directly proportional to the tensile force and the length of the bar and inversely proportional to the cross-sectional area and the modulus of elasticity.Up to a limiting stress, a body will be able to . The hardness (H) of a material tends to increase with an increase in the elastic modulus (E), yield strength (σ y) and the strain-hardening exponent (n). Several materials with different combinations of elastic and plastic properties can exhibit identical true hardness (for a particular indenter geometry/apex angle).

well as tension, hardness, torsion, and impact tests in particular. Mechanical Testing Mechanical tests (as opposed to physical, electrical, or other types of tests) often involves the deformation or breakage of samples of material (called test specimens or test pieces). Some common forms of test specimens and loading situations are shown in .

Young’s modulus is equal to the longitudinal stress divided by the strain. Hardness of Beryllium Bronze. Rockwell hardness of copper beryllium – UNS C17200 is approximately 82 HRB. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the .Indentation test (Hardness test) . hard to get a nano-scale response from different grains. . measure of elastic modulus. Anthony C. Fischer-Cripps, Principles of nanoindentation, training lecture. Basic Hertz’s elastic solution (1890s) Schematics of indenter tips From determining the strength and durability of materials to evaluating their elasticity, there are a lot of different methods used to test the mechanical properties of materials. . including elastic modulus, shear modulus, yield strength, ductility, and hardness. Each of these properties is tested using different methods and techniques .

An analytical relationship between the reduced modulus E r and hardness H for solid materials is established based on the conventional depth-sensing indentation method of Oliver and Pharr. It is found that the two properties are related through a material parameter that is defined as the recovery resistance R s.This parameter is shown to represent the energy .The Young’s modulus of elasticity of Gold is 205 MPa. Hardness of Gold. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical . To calculate Young’s modulus of elasticity, follow these steps: 1. Measure the Original Length of Your Material with a Micrometer. Use a micrometer to measure the original length (L0) of the material you’re working with, but do this before any force is applied or stretching occurs so that you can get the most accurate answer. 2. Use the . The zero-point of indentation depth in nanoindentation or depth-sensing instrumented indentation tests should be precisely set to evaluate the indentation hardness and indentation elastic modulus .

kd tools diesel compression tester

elastic modulus vs stiffness

WEB19 de jan. de 2024 · A GGBet destaca-se entre cassinos e casas de apostas online por sua grande variedade de jogos e métodos de pagamento. Com isso, ganha cada vez mais jogadores.

how to get elastic modulus from hardness test|elastic modulus